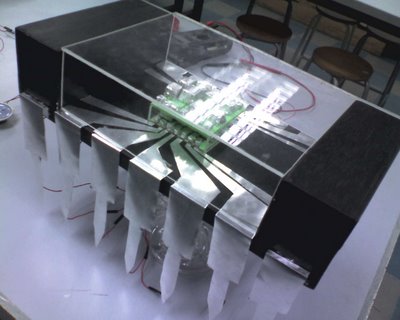

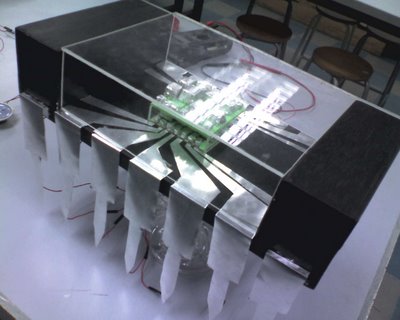

Finish Product.

The Dummy IC + Circuit.

The Dummy IC.

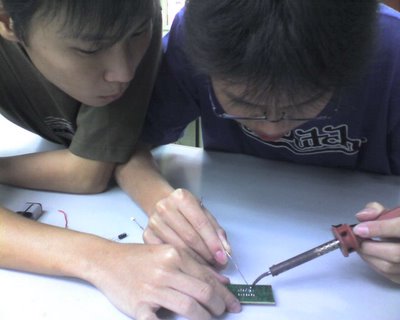

And also, we did a short documentary on how the IC would actually be used in application. Sadly some portion of the video the voice couldn't be heard clearly. Here's the video anyways.

| INPUT | OUTPUT | |

|---|---|---|

| A | B | A NAND B |

| 0 | 0 | 1 |

| 1 | 0 | 1 |

| 0 | 1 | 1 |

| 1 | 1 | 0 |

Design Proposal

SmartSolutions

Design statement

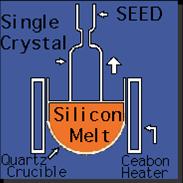

This enlarged dummy IC will show the rough anatomy of an IC which is easily viewed by the naked eye. Thus, it will provide further information regarding the workings of an IC.

Proposed by: Chong Jin Yang Accepted by:

Tan Ken Seong

Lai Tong Jiun

Design Proposal

SmartSolutions

Design statement

There is a fan which is connected to a light sensitive circuit. When there is light coming from a source, the fan will be automatically activated by the integrated circuit. Both the main switch and the photo sensor are directly connected to the AND logic gate in the IC. The fan will activate as long as the main switch is on and the photo sensor detects light. The IC will in turn be connected to the fan.

In terms of application, this device is very useful in offices or buildings. When a person enters an enclosed room and turns on the light, the device will detect light and hence will switch on the cooling fan. When the person leaves the room, he or she will switch off the light. As there is no light source, the device will automatically switch off the fan and thus save energy.

Proposed by: Chong Jin Yang Accepted by:

Tan Ken Seong

Lai Tong Jiun