After testing the prototype with the Plaster of Paris, it is found that the material is not suitable for the contruction of the Dummy IC. This is because the group faced many problems in using the material which are:

1. The prototype created is very uneven because there is no proper mould to make it. (shoebox was used)

2. The material is too heavy. This is cause problem during transportation as well as the contruction of the Dummy IC's legs.

3. The material takes too long to dry. After leaving the prototype in open air for a week. It is still wet. And thus not suitable for spraying colour.

4. Colour spray doesn not absorb evenly on the surface of the Dummy IC. This is related to the wetness of the surface of the Dummy IC.

After dropping the plans to build the prototype with Plaster of Paris, A new material is then chosen to construct the Dummy IC. Wood. These are the reaons why wood was chosen:

1. The surface of the prototype that is contructed is even this is because wood is properly cut flat.

2. The material although heavy, but it was not as heavy as the pervious prototype material which was Plaster of Paris

3. The material is ready for spraying immediately.

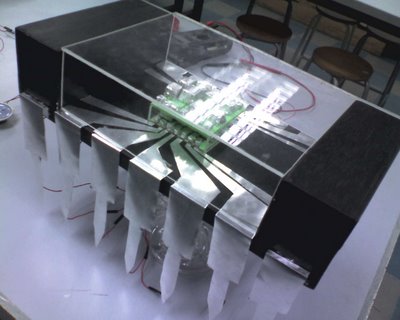

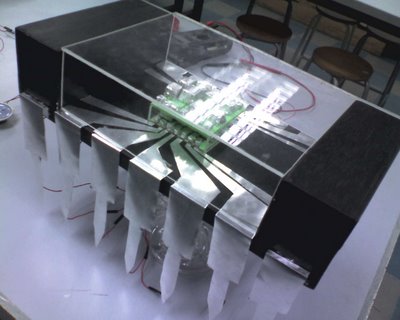

The prototype with it's leg placed for measurement.

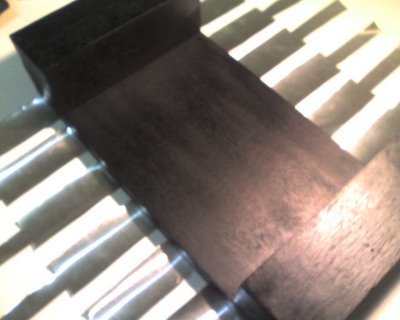

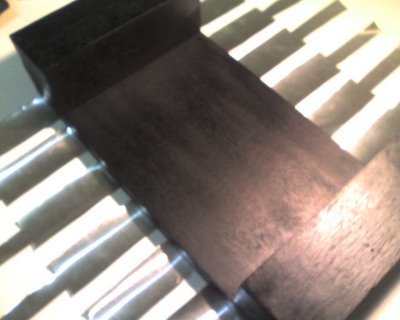

The spacing between the wood to make way for the IC Dye and the insides of the Dummy IC